Jessore Road, Kolkata, West Bengal

- GST NO. : 19AAGCB9681F1Z9

Laminar Air Flow Cabinet

Leading Manufacturers, Exporters, Wholesaler, Retailer and Distributor of Horizontal Laminar Air Flow, laminar air flow, reverse laminar flow booth and Vertical Laminar Air Flow from Kolkata.

| Business Type | Manufacturer, Exporter |

| Certification | ISO 9001:2015 |

| Application | Labotary |

| Condition | New |

| Warranty | 1yr |

| Brand Name | UR Biocoction |

| Country of Origin | India |

| Product Code | LAF H / LAF V |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, Other |

| Delivery Time | 2-3 weeks |

| Packaging Details | Wooden caret |

Preferred Buyer From

| Location | India ( West Bengal), Bangladesh, Bhutan, Nepal |

Details

- Ergonomic design for versatile usage, ease of use, plug & play system.

- Designed so as to meet the requirements of US Federal Standard 209 B (BS 5295) providing particle free air to meet class 100 conditions

- International Standards - UK Complied Certifications – ISO 9001:2015, CE. GMP.

- Company is under Make in India & MSME Certified with International standard, certified model with duly mentioned brand name. Internal IQ/OQ/PQ Certification

- Material Of Construction:- Outer Body- CRCA Sheetepoxy Powder coated antibacterial& Antirust effect, 22 gauge ORStainless Steel-304PVC /Matt grit/ Sattin finish, 22 GAUGE

- Work table top:-SS-304, PVC /Matt grit/ Sattin finish, 22 GAUGE

- Front door and side covered with UV – protected 5 mm

- Acrylic sheet to protect customer from UV Exposure – complete transparent. Permanent magnet to hold

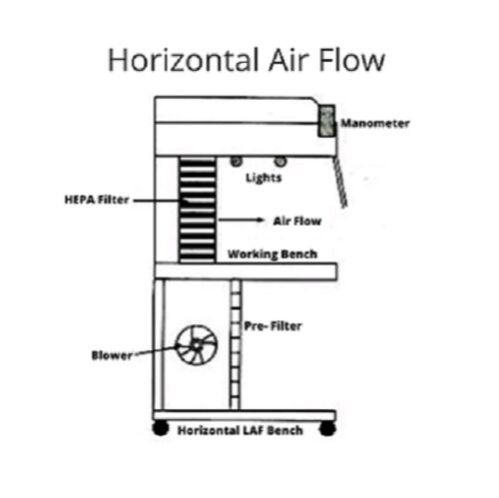

- Air flow type: - Horizontal Air flow from the front.

- Air Flow Velocity:- 90 FPM ±20%, Inflow Velocity: 0.53 m/s,Down flow Velocity: 0.33m/s

- Statically balanced motor blower Assembly (Heavy Duty), 1440 rpm, ¼ hp. Noise of the blower is less than 55 dBA& Very low vibration

- Filtration Assembly: - Room air is drawn from the bottom of the cabinet through a Pre- Filter, then the air pass through HEPA Filter and spread evenly in the working area providing a constant a stream of clean air flow within the work area.

- Prefilter is made from Non-Woven Synthetic with HDPE mesh and Al expanded mesh on air leaving side; conforms to EU – 4 / G-4 Grade, with the efficiency of down to 10 microns. These filters can be cleaned by compressed air & also washable.

- HEPA Filteris Mini pleat type, made from water-resistant, fire retardant, imported micro-fine glass fiber media; conforms to EU – 14 Grade, with an efficiency rating better than 99.999% for 0.3 μ. These filters are designed to accommodate higher air flow volume.

- Perforated diffuser screen /shield mesh guard protect Filters from damage.

- Front angular 10 degree slope helps reduce fatigue of user.

- Pressure manometer to track filter pressure & air/gas cock inside the working area

- Top removable panel for easy access to electrical fittings and easy removable filter placement for ease of access during service.

- Wheels: -Mounted on heavy tubular stand with lockable castors.

- Electricals fittings & Fixtures: -

- Microprocessor based PID Controller – UV ON-OFF, UV-Timer, Blower 3 speed control – High, Low, Medium, and Display of UV Age.

- Fluorescent light – 20 watt, ˃800 lux, with chokes for lighting

- UV Light – 15 watt, Philips make

- Power supply -220-230 V, 50-60 Hz, 5/15 amps power cord.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Certification | ISO 9001:2008 Certified |

| Application | In Laboratory |

| Feature | Rust Proof |

| Condition | New |

| Warranty | 1year |

| Brand Name | UR Biocoction |

| Size | 2 ft |

| Product Code | LAFH |

| Port | kolkata |

| Payment Terms | L/C, D/A, D/P |

| Delivery Time | 10-15 Days |

| Packaging Details | standard packing |

Preferred Buyer From

| Location | India ( West Bengal), Bangladesh, Bhutan, Nepal |

Work table top:- SS-304,22 GAUGE

Front door and side covered with UV – protected 5 mm Acrylic sheet to protect customer from UV Exposure – complete transparent. Permanent magnet to hold

Air flow type: - Horizontal Air flow from the front.

| Business Type | Manufacturer, Exporter |

| Type | Reverse Laminar Air Flow Unit |

| Certification | ISO 9001:2015 |

| Application | Purifies Water |

| Weight | 1000-2000kg |

| Voltage | 220V |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Driven Type | Electric |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | UR Biocoction |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 2 to 3 week |

| Packaging Details | Carton Box |

Preferred Buyer From

| Location | India ( West Bengal), Bangladesh, Bhutan, Nepal |

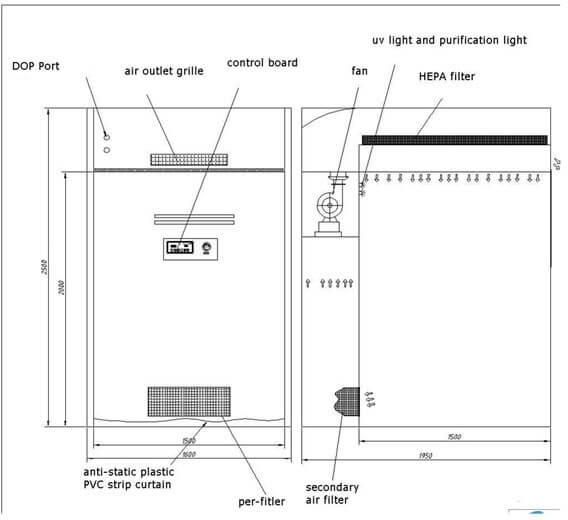

Ergonomic design for versatile usage eases of use, plug & play system.International Standards - UK Complied Certifications – ISO 9001:2015, CE. GMP.Company is under Make in India & MSME Certified with International standard, certified model with duly mentioned brand name .Internal IQ/OQ/PQ Certification.Double wall system, Outer MS- Powder coated and Inner Stainless steel-304. Between two walls are filled with Glass wool insulation.

| Business Type | Manufacturer, Exporter |

| Type | Laminar Flow Bench |

| Material | Stainless Steel, MS |

| Application | Labotary |

| Feature | Easy To Install, Labotary |

| Condition | New |

| Warranty | 1yr |

| Product Code | LAFV |

| Port | Kolkata |

| Payment Terms | L/C, D/A, D/P, T/T, Other |

| Delivery Time | 2 to 3 week |

| Packaging Details | Wooden Caret |

Preferred Buyer From

| Location | India ( West Bengal), Bangladesh, Bhutan, Nepal |

Details :

- Ergonomic design for versatile usage, ease of use, plug & play system.

- Designed so as to meet the requirements of US Federal Standard 209 B (BS 5295) providing particle free air to meet class 100 conditions

- International Standards - UK Complied Certifications – ISO 9001:2015, CE. GMP.

- Company is under Make in India & MSME Certified with International standard, certified model with duly mentioned brand name.Internal IQ/OQ/PQ Certification.

- Material Of Construction:- Outer Body- CRCA Sheetepoxy Powder coated antibacterial& Antirust effect, 22 gauge ORStainless Steel-304 finish, 22 GAUGE

- Work table top: -SS-304, PVC /Matt grit/ Sattin finish, 22 GAUGE. Single piece without any internal joint or welding

- Front door – Counter balanced weight with 5 mm toughened/tempered glassUV protectedtoprotect customer from UV Exposure –complete transparent along with base structure to hold the cabinet & ease of access.

- Air flow type: - Vertical Air flow from the top.

- Air Flow Velocity:- 90 FPM ±20%, Inflow Velocity: 0.53 m/s,Down flow Velocity: 0.33 m/s

- Statically balanced motor blower Assembly (Heavy Duty), 1440 rpm, ¼ hp. Noise of the blower is less than 55 dBA & Very low vibration

- Front angular 10 degree slope helps reduce fatigue of user.

- Pressure manometer to track filter pressure & air/gas cock inside the working area

- Easy removable back/front panel for easy access to electrical fittings and easy removable filter placement for ease of access during service.

- Wheels: -Mounted on heavy tubular stand with lockable castors with foot rest

Filtration Assembly: -

- Room air is drawn from the top of the cabinet through a Pre- Filter, then the air pass through HEPA Filter and spread evenly in the working area providing a constant a stream of clean air flow within the work area.

- Prefilter is made from Non-Woven Synthetic with HDPE mesh and Al expanded mesh on air leaving side; conforms to EU – 4 / G-4 Grade, with the efficiency of down to 10 microns. These filters can be cleaned by compressed air & also washable.

- HEPA Filteris Mini pleat type, made from water-resistant, fire retardant, imported micro-fine glass fiber media; conforms to EU – 14 Grade, with an efficiency rating better than 99.999% for 0.3 μ. These filters are designed to accommodate higher air flow volume.

- Perforated diffuser screen /shield mesh guard protect Filters from damage.

Electricals fittings & Fixtures: -

- Microprocessor based PID Controller – UV ON-OFF, UV-Timer, Blower 3 speed control – High, Low, Medium, and Display of UV Age.

- Fluorescent light – 20 watt, ˃800 lux, with chokes for lighting

- UV Light – 15 watt, Philips make

- Power supply -220-230 V, 50-60 Hz, 5/15 amps power cord.

- Internal 5 amp electrical connection for usage of several machines in clean air